Edinburgh/Yoghurt

From 2007.igem.org

Introduction | Applications | Design | Modelling | Wet Lab | Proof of concept | Future Directions | References

Introduction | Applications | Design | Modelling | Wet Lab | Proof of concept | Future Directions | References

| Welcome to the self-flavouring yogurt project

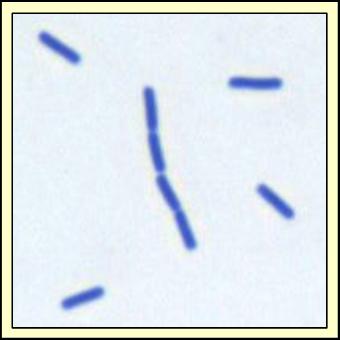

There are several advantages for using genetically engineered gram positive bacteria, over the traditionally used E. coli.

|

Yoghurt ProductionTraditionally making yoghurt was a method used to preserve milk for longer, as the fermentation culture used lowered the pH of the yoghurt, which inhibited the growth of food spoiling, not to mention potentially hazardous, micro-organisms. Yoghurt is produced by introducing lactic acid bacteria (LAB) into milk (these include the legally required strains Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus salivarius subsp. thermophilus). LAB then partially digest the casein proteins within the milk and metabolise lactose to lactic acid, leading to a decrease in pH (to around pH4.5), causing the casein proteins to gel together and form yoghurt.

Yoghurt may also be enjoyed by many lactose intolerant people, as the enzymes released by the LAB are thought to aid digestion of lactose within the gut.

|

Introduction | Applications | Design | Modelling | Wet Lab | Proof of concept | Future Directions | References