Edinburgh/Yoghurt/Design

From 2007.igem.org

(→Vanilla Flavour Production) |

|||

| Line 76: | Line 76: | ||

We chose to use tyrosine as a starting point, as the amino acid is produced endogenously by bacteria, and is also present within milk proteins. Theoretically this means a starting substrate will not have to be added to the yoghurt starter culture, to faciliate the synthesis of vanillin. | We chose to use tyrosine as a starting point, as the amino acid is produced endogenously by bacteria, and is also present within milk proteins. Theoretically this means a starting substrate will not have to be added to the yoghurt starter culture, to faciliate the synthesis of vanillin. | ||

| - | The vanillin biosynthesis pathway was created by peicing together five different genes from three completely different organisms. These five genes | + | The vanillin biosynthesis pathway was created by peicing together five different genes from three completely different organisms. These five genes are: |

| + | * Sam8 | ||

| + | * Sam5 | ||

| + | * COMT | ||

| + | * Fcs | ||

| + | * Ech | ||

| + | |||

| + | <u>Sam8</u> | ||

| + | * isolated from the bacterium ''Saccharothrix espeanensis'' | ||

| + | * encodes tyrosine ammonia lyase (catalyses the deamination of tyrosines amine group) | ||

| + | * converts tyrosine to p-coumaric acid (fig. 3) | ||

| + | * catalyses the first step in the vanillin biosynthesis pathway | ||

| + | |||

| + | <u>Sam5</u> | ||

| + | * also isolated from ''Saccharothrix espeanensis'' | ||

| + | * encodes 4-coumarate 3-hydroxylase (hydroxylates C4 in the aromatic ring of p-coumaric acid) | ||

| + | * converts p-coumaric acid to caffeic acid (fig. 3) | ||

| + | * catalyses the second step in the vanillin biosynthesis pathway | ||

| + | |||

| + | <u>COMT</u> | ||

| + | * enzyme is natively found in the plant alfalfa | ||

| + | * encodes caffeic acid-O-methyl transferase (methylates -OH on C4 of the aromatic ring) | ||

| + | * produces ferulic acid from caffeic acid (fig. 3) | ||

| + | * catalyses the third step of the vanillin biosynthesis pathway | ||

| + | |||

| + | <u>fcs</u> | ||

| + | * gene was isolated from ''Pseudomonas fluorescens'' | ||

| + | * encodes feruoyl CoA synthase | ||

| + | |||

| + | |||

| + | |||

===Lemon Flavour Production=== | ===Lemon Flavour Production=== | ||

Revision as of 14:14, 1 October 2007

Introduction | Applications | Objectives | Design | Modelling | Wet Lab | References

Introduction | Applications | Objectives | Design | Modelling | Wet Lab | References

Contents |

Colour Production

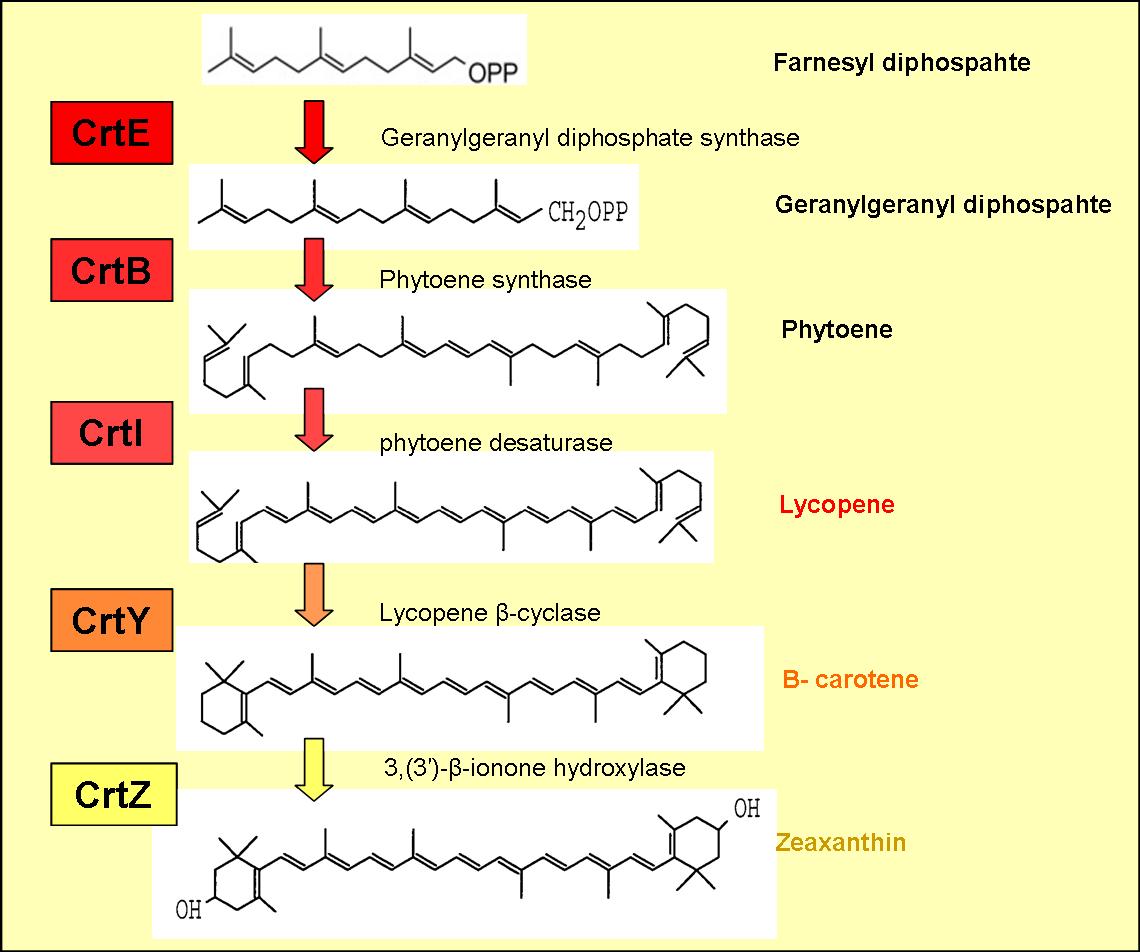

The zeaxanthin operon is naturally found in many plants and bacteria. The operon encodes five genes, which enable the production of the yellow pigment zeaxantin.

The five genes present in the zeaxanthin operon are:

- CrtE

- CrtB

- CrtI

- CrtY

- CrtZ

The enzymes encoded by these genes and the products formed are displayed in figure 1.

There are three pigments produced by the genes with in the zeaxanthin operon and a brief description of each is given below:

Lycopene

The genes CrtE, CrtB and CrtI produce lycopene from farnesyl diphosphate (an intermediate in the mevlonate pathway).

Lycopene is a red pigment (found in tomatoes), which also has extremally powerful antioxidant properties and may possibly help protect you from cancer.

B-carotene

B-carotene is produced by cyclising lycopene, which is carried out by lycopene B-cyclase encoded by the gene CrtY (see figure )

B-carotene has an orange pigmentation and is responsible for the colour of carrots, winter squash and several other vegetables. The pigment can be stored in the liver and converted to Vitamin A, a form of retinol, required for sight.

zeaxanthin

Addition of CrtZ to the CrtEBIY construct enables the hydroxylation of B-carotene (see figure 1) to zeaxanthin, which is a yellow pigment.

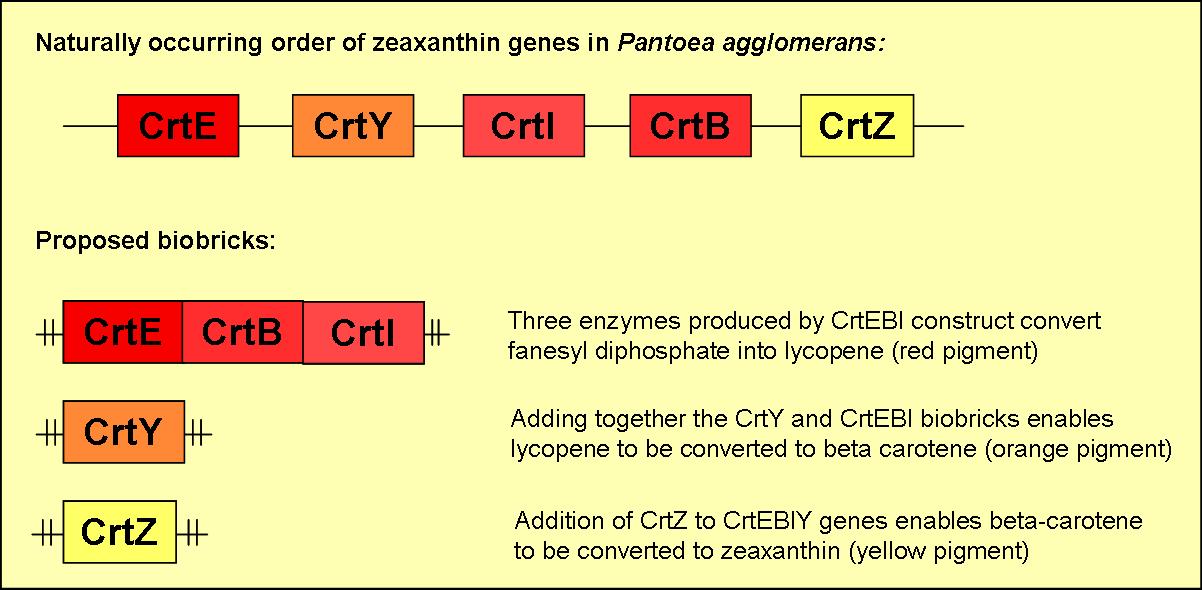

Proposed Biobricks

We plan to produce five different biobricks with varying combinations of the five zeaxanthin genes. A brief overview of three of these biobricks can be found in figure 2.

Biobrick 1

- will consist of the three genes CrtE, CrtB & CrtI

- will produce the red pigment lycopene

Biobrick 2

- will contain CrtY

- when induced in the presence of functional CrtEBI genes an orange pigment (B-carotene) will be formed

Biobrick 3

- will consist of CrtZ

- when induced in the presence of functional CrtEBIY genes it will enable the formation of the yellow pigment zeaxanthin

Biobrick 4

- will contain the four genes CrtE, CrtB, CrtI & CrtY

- the construct will be capable of producing B-carotene

Biobrick 5

- will contain all five genes present in the zeaxanthin operon; CrtE, CrtB, CrtI, CrtY & CrtZ

- biobrick will enable the production of zeaxanthin (yellow pigmentation)

Vanilla Flavour Production

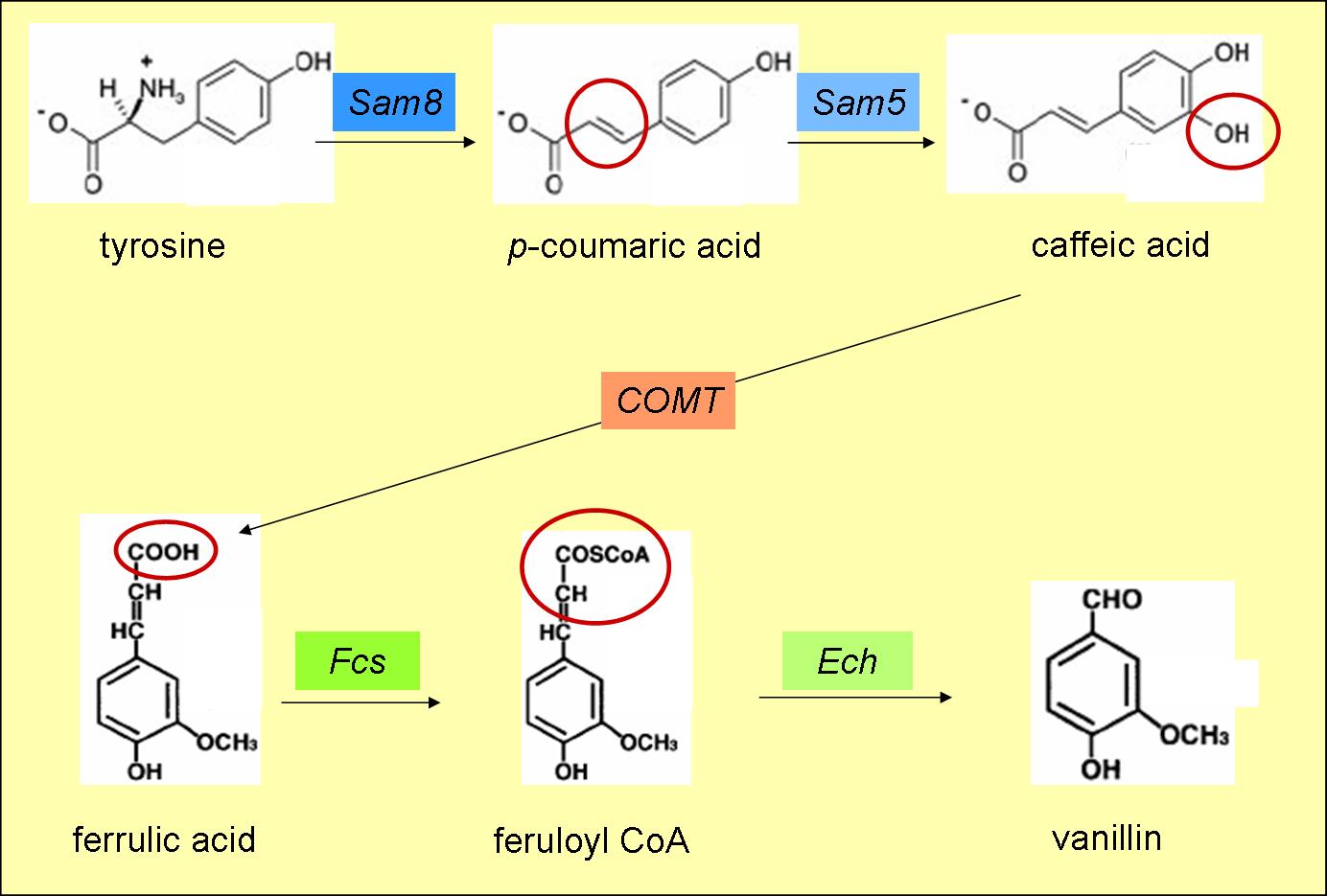

In order to create vanilla flavouring for our yoghurt, we have designed a novel vanillin biosynthesis pathway. This pathway consists of five different genes, which enable the synthesis of vanillin from the amino acid tyrosine.

We chose to use tyrosine as a starting point, as the amino acid is produced endogenously by bacteria, and is also present within milk proteins. Theoretically this means a starting substrate will not have to be added to the yoghurt starter culture, to faciliate the synthesis of vanillin.

The vanillin biosynthesis pathway was created by peicing together five different genes from three completely different organisms. These five genes are:

- Sam8

- Sam5

- COMT

- Fcs

- Ech

Sam8

- isolated from the bacterium Saccharothrix espeanensis

- encodes tyrosine ammonia lyase (catalyses the deamination of tyrosines amine group)

- converts tyrosine to p-coumaric acid (fig. 3)

- catalyses the first step in the vanillin biosynthesis pathway

Sam5

- also isolated from Saccharothrix espeanensis

- encodes 4-coumarate 3-hydroxylase (hydroxylates C4 in the aromatic ring of p-coumaric acid)

- converts p-coumaric acid to caffeic acid (fig. 3)

- catalyses the second step in the vanillin biosynthesis pathway

COMT

- enzyme is natively found in the plant alfalfa

- encodes caffeic acid-O-methyl transferase (methylates -OH on C4 of the aromatic ring)

- produces ferulic acid from caffeic acid (fig. 3)

- catalyses the third step of the vanillin biosynthesis pathway

fcs

- gene was isolated from Pseudomonas fluorescens

- encodes feruoyl CoA synthase

Lemon Flavour Production

Gene Expression In Lactobacillus

In order to express our flavour and colour genes in lactic acid bactia (LAB), we require a different vector to those currently in use by the registry. After some research, we found that a few groups withint the UK were working with LAB.

We kindly thank Dr Mike Gasson & Dr. Claire Shearman, of the Institute of Food Research in Norwich for generously donating the pTG262 vector.

pTG262

This vector was ideal for use as a biobrick chassey, as:

- it contained three of the four biobrick restriction enzyme sites (insertion of a biobrick added the other two)

- it has a gram positive origin of replication, which works well in E. coli (enabling the plasmid to act as a shuttle vector between E. coli and LAB

- contains three antibiotic resistance sites (chloramphenicol, neomycin & gentamicin)

- known to work in Lactobacillus, Lactococcus and Bacillus as well as E. coli

We also plan to test the efficieny of the vector in other gram negative bacteria including; Shewanella & Pseudomonas, Agrobacterium

Introduction | Applications | Objectives | Design | Modelling | Wet Lab | References