Edinburgh/Yoghurt

From 2007.igem.org

(→Self flavouring yoghurt) |

|||

| (75 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

| - | [[Edinburgh]] | + | ---- |

| + | [[Image:Edinburgh Uni Logo.jpg|80 px]] | ||

| + | [[Edinburgh/Yoghurt| Introduction]] | [[Edinburgh/Yoghurt/Applications|Applications]] | [[Edinburgh/Yoghurt/Design|Design]] | [[Edinburgh/Yoghurt/Modelling|Modelling]] | [[Edinburgh/Yoghurt/Wet Lab|Wet Lab]] | [[Edinburgh/Yoghurt/Proof of concept|Proof of concept]] | [[Edinburgh/Future| Future Directions]] | [[Edinburgh/Yoghurt/References|References]] | ||

| + | ---- | ||

| - | + | {| style="background:#faf5ff ; border:1px solid #afa3bf; padding: 1em; margin: auto" | |

| - | + | |- | |

| - | |||

| - | = | + | | <big><span style="color:black">'''Welcome to the self-flavouring yogurt project'''</span></big> |

| - | |||

| - | |||

| + | <big><span style="color:#708090">''The aim of this project is not only to produce colourful, tasty yoghurt, but to demostrate it is possible to introduce BioBricks into gram positive organisms.'' | ||

| + | </span></big> | ||

| - | |||

| - | + | We chose to produce 'self-flavouring' yoghurt, as this project enables us to genetically manipulate a range of gram positive bacteria required for yoghurt formation (see yoghurt production, below). | |

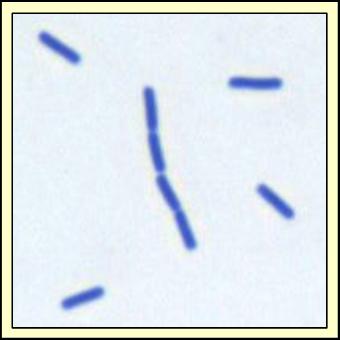

| - | + | [[Image:Bacillus subtilis.jpg|thumb|Bacillus subtilis|150 px]] | |

| - | + | There are several advantages for using genetically engineered gram positive bacteria, over the traditionally used ''E. coli''. | |

| + | |||

| + | * Some Gram positive organisms (eg ''Lactobacillus, Lactococcus'') are food grade, and therefore may be ingested. ''Lactobacillus'' are alsp common and harmless (indeed, beneficial) components of the human gut flora. Potentially this could enable their use in a range of products from medicines to milk shakes or yoghurt to deliver beneficial molecules to the body. Of course, there are also regulatory issues related to consumption of genetically modified organisms, but these will be more easily addressed in a known-harmless host with a long history of safe food use. | ||

| + | |||

| + | |||

| + | * Several gram positive bacteria, such as ''Bacillus spp.'' are able to form hardy endspores, which are extremely tolerant of heat, drying and other stresses, and can survive for centuries. These do not require refrigeration and can be transported and used in very hot, cold or developing countries cheaply and with ease. | ||

| + | |||

| + | |||

| + | * Gram positive organisms, such as the lactic acid bacteria, are much more efficient at secreting proteins and other molecules into their surrounding media than ''E. coli''; most strains of ''E. coli'' lack the Main Terminal Branch of the General Secretory Pathway and secrete only a few proteins using specific mechanisms such as ABC transporters (eg, for hemolysin) and Type 3 Secretion Systems (in pathogenic strains). | ||

| + | |} | ||

| + | |||

| + | |||

| + | {|style="background:#fffaf5; border:1px solid #CFB53B; padding: 1em; margin: auto" | ||

| + | |- | ||

| + | | | ||

| + | |||

| + | ====Yoghurt Production==== | ||

| + | [[Image:Cow.jpg|thumb|The cow - an indirect producer of yoghurt]] | ||

| + | |||

| + | Traditionally making yoghurt was a method used to preserve milk for longer, as the fermentation culture used lowered the pH of the yoghurt, which inhibited the growth of food spoiling, not to mention potentially hazardous, micro-organisms. | ||

| + | |||

| + | Yoghurt is produced by introducing lactic acid bacteria (LAB) into milk (these include the legally required strains ''Lactobacillus delbrueckii subsp. bulgaricus'' and ''Streptococcus salivarius subsp. thermophilus''). LAB then partially digest the casein proteins within the milk and metabolise lactose to lactic acid, leading to a decrease in pH (to around pH4.5), causing the casein proteins to gel together and form yoghurt. | ||

| + | |||

| + | |||

| + | [[Image:Yoghurt.jpg|left|thumb| some yummy yoghurt to feast your eyes on ]] | ||

| + | |||

| + | |||

| + | Today yoghurt has many reported health benefits. For example, the inclusion of ''Bifidobacterium'', | ||

| + | ''Lactobacillus acidophilus'' and ''Lactobacillus casei'' in the yoghurt starter culture, creates a probiotic - a dietary supplement that contains several potentially beneficial bacteria, which may help replenish the body's natural gut flora. | ||

| + | |||

| + | Yoghurt may also be enjoyed by many lactose intolerant people, as the enzymes released by the LAB are thought to aid digestion of lactose within the gut. | ||

| + | |||

| + | |||

| + | More information about yoghurt may be found at [http://en.wikipedia.org/wiki/Yogurt wikipedia] | ||

| + | |||

| + | |} | ||

| + | |||

| + | ---- | ||

| + | [[Edinburgh/Yoghurt| Introduction]] | [[Edinburgh/Yoghurt/Applications|Applications]] | [[Edinburgh/Yoghurt/Design|Design]] | [[Edinburgh/Yoghurt/Modelling|Modelling]] | [[Edinburgh/Yoghurt/Wet Lab|Wet Lab]] | [[Edinburgh/Yoghurt/Proof of concept|Proof of concept]] | [[Edinburgh/Future| Future Directions]] | [[Edinburgh/Yoghurt/References|References]] | ||

| + | ---- | ||

| + | |||

| + | <!--==Application== | ||

| + | |||

| + | There are many potential advantages for genetically modifying bacteria and other micro-organisms that are normally present in our food. These include increasing the number of beneficial vitamins, carotenoids and other co-factors, which may be rare in some peoples diet, such as those people suffering from malnutrition in developing countries. | ||

| + | Other uses include the manufacture of medicines in the small intestine, which cannot survive in the gut, or biotechnological applications such as the production of naturally synthetic colours and flavours. | ||

==Vanillin Project== | ==Vanillin Project== | ||

| Line 34: | Line 79: | ||

Both ''fcs'' and ''ech'' genes are present in a variety of microorganisms. After much searching we have identified ech and fcs genes in ''Pseudomonas fluorescens'', which have a minimal number of forbidden restriction sites. The PstI site within ech is located at the 3' terminal and shall be mutated out during the PCR amplification of the gene from ''P. fluorescens''. | Both ''fcs'' and ''ech'' genes are present in a variety of microorganisms. After much searching we have identified ech and fcs genes in ''Pseudomonas fluorescens'', which have a minimal number of forbidden restriction sites. The PstI site within ech is located at the 3' terminal and shall be mutated out during the PCR amplification of the gene from ''P. fluorescens''. | ||

| + | |||

| + | |||

| + | ==Progress so far== | ||

| + | |||

| + | ====Sam5 & Sam8==== | ||

| + | * ''Saccharothrix espeanensis'' has arrived from DSMZ culture collection | ||

| + | :: requires reviving and fcs and ech genes being PCR'd out | ||

| + | |||

| + | * Sam8 and Sam5 expression vector kindly donated by Dr Anton Linnenbrink from the Institute for Pharmazeutische Wissenschaften in Germany | ||

| + | :: vector has been transformed into ''E. coli'' | ||

| + | :: need to PCR out genes when primers arrive | ||

| + | |||

| + | ====COMT==== | ||

| + | * have grown up alfalfa seeds and genomic plant DNA has been extracted | ||

| + | :: attempted to amplify up COMT via PCR, but have had no promising results so far | ||

| + | |||

| + | * RNA has been isolated from alfalfa | ||

| + | :: have attempted to amplify up cDNA of COMT gene and are waiting on results | ||

| + | |||

| + | ====fcs & ech==== | ||

| + | * Pseudomonas fluorescens has arrived from NCIMB culture collection and has been revived | ||

| + | |||

| + | ====fcs==== | ||

| + | * have carried out several PCRs to amplify out the fcs gene from ''Pseudomonas fluorescenes'' | ||

| + | :: PCRs did not result in one PCR product being produced, problem is most probably due to the ''P. fluorescens'' genome being of high GC content | ||

| + | :: are attempting to purify out fcs gene from agrose gel of PCR products | ||

| + | |||

| + | ====ech==== | ||

| + | * the first set of primers ordered for ech did not work, as no PCR product was present after several PCR reactions | ||

| + | |||

| + | * have sent away for a second set of primers and are awaiting their arrival | ||

| + | |||

| + | |||

| + | ====vector==== | ||

| + | * we are going to modify a vector kindly donated by Norwich University, which can act as a shuttle vector between ''E. coli'' and a broad range of gram positive hosts, including ''Bacillis subtillis'', ''Lactobacillus'' and ''Lactococcus'' | ||

| + | |||

| + | * firstly we will ligate MITs wintergreen scent generating device into the vector to characterise how the vector works in our chosen gram positive organisms | ||

| + | * secondly, when we have a working vanillin synthesis pathway, the vanillin biosynthesis pathway will be inserted into the vector and then transformed into ''Lactobacillus'' under the control of the arabinose promoter | ||

| + | :: ''Lactobacillus'' may then be used to make yoghurt giving us self flavouring yoghurt, when the arabinose inducer is added | ||

====Enzyme Accession Numbers==== | ====Enzyme Accession Numbers==== | ||

| Line 58: | Line 142: | ||

Downregulation of Caffeic Acid 3-O-Methyltransferase and Caffeoyl CoA 3-O-Methyltransferase in Transgenic Alfalfa Impacts on Lignin Structure and Implications for the Biosynthesis of G and S Lignin, Guo D, et al, Plant Cell. January; 13(1): 73 (2001) | Downregulation of Caffeic Acid 3-O-Methyltransferase and Caffeoyl CoA 3-O-Methyltransferase in Transgenic Alfalfa Impacts on Lignin Structure and Implications for the Biosynthesis of G and S Lignin, Guo D, et al, Plant Cell. January; 13(1): 73 (2001) | ||

| + | --> | ||

Latest revision as of 23:33, 26 October 2007

Introduction | Applications | Design | Modelling | Wet Lab | Proof of concept | Future Directions | References

Introduction | Applications | Design | Modelling | Wet Lab | Proof of concept | Future Directions | References

| Welcome to the self-flavouring yogurt project

There are several advantages for using genetically engineered gram positive bacteria, over the traditionally used E. coli.

|

Yoghurt ProductionTraditionally making yoghurt was a method used to preserve milk for longer, as the fermentation culture used lowered the pH of the yoghurt, which inhibited the growth of food spoiling, not to mention potentially hazardous, micro-organisms. Yoghurt is produced by introducing lactic acid bacteria (LAB) into milk (these include the legally required strains Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus salivarius subsp. thermophilus). LAB then partially digest the casein proteins within the milk and metabolise lactose to lactic acid, leading to a decrease in pH (to around pH4.5), causing the casein proteins to gel together and form yoghurt.

Yoghurt may also be enjoyed by many lactose intolerant people, as the enzymes released by the LAB are thought to aid digestion of lactose within the gut.

|

Introduction | Applications | Design | Modelling | Wet Lab | Proof of concept | Future Directions | References