Imperial/Infector Detector/F2620 Comparison

From 2007.igem.org

Summary of Comparison

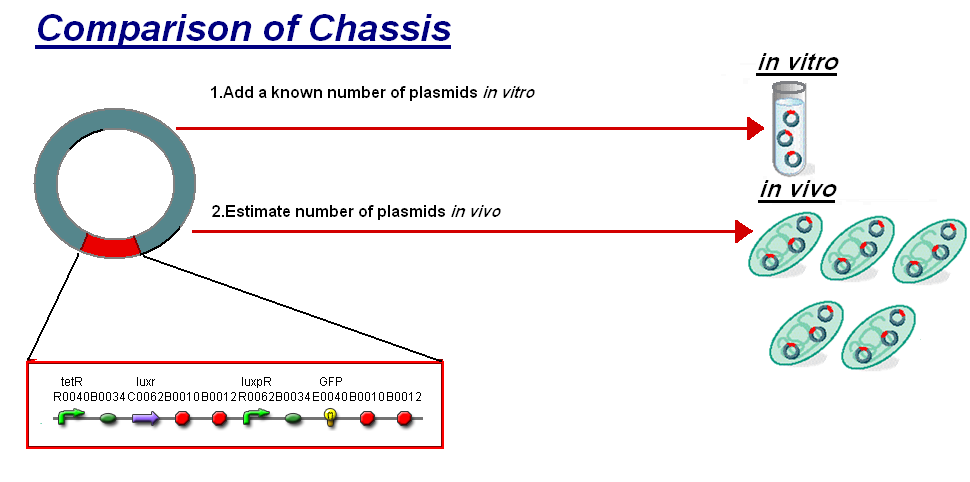

We compared our in vitro characterisation to the characterisation of [http://partsregistry.org/Part:BBa_F2620 F2620] in vivo with the aim to highlight some of the differences between the chassis and investigate how the constructs characteristics may change between them. The [http://partsregistry.org/Part:BBa_F2620 F2620] is an ideal construct to compare for comparison because of its detailed characterisation in vivo. The construct is the same as the construct 1 that was used for infecter detector, pTet-LuxR-pLux-GFPmut3b. The key results the comparison were;

- The creation of a new unit to allow comparison between in vitro and in vivo chassis.

- The constructs response appears to be largely independent of the chassis used.

Both of these are important findings and highlight the potential that new chassis offer to synthetic biology.

|

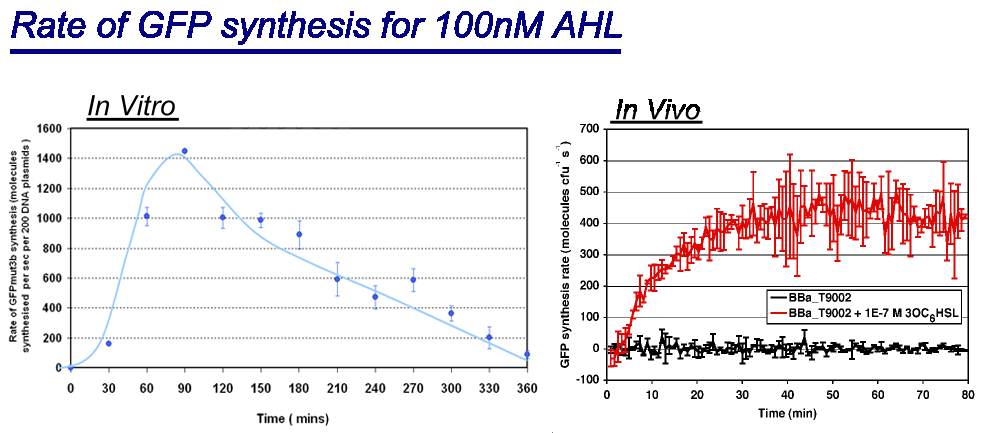

| Comparison between in vivo and in vitro for rate of GFPmut3b synthesis for 100nM AHL. The in vivo chassis used was the bacterial strain MG1655 and the in vitro chassis was Promega Commercial S30 Cell Extract.

|

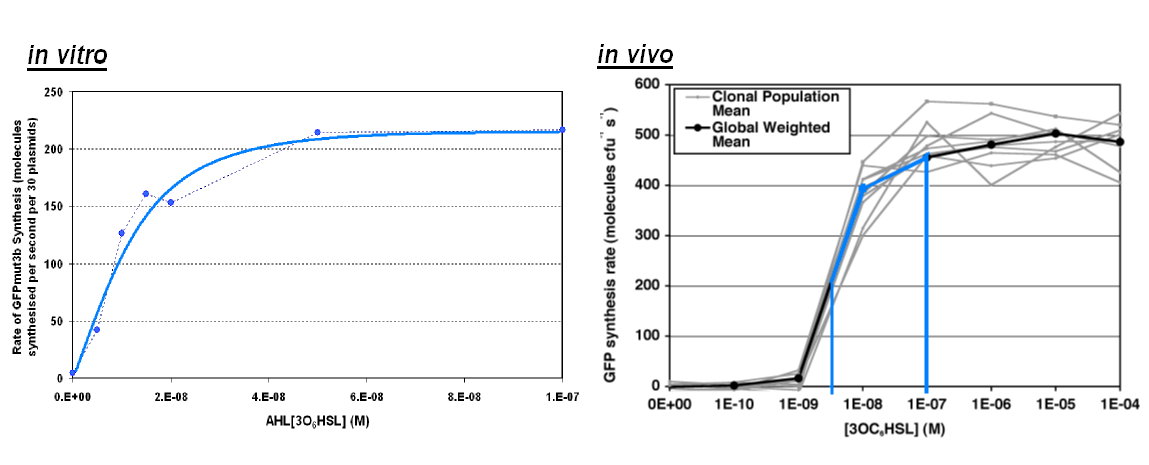

Transfer Function

The graph above shows the transfer function of [AHL] input vs rate of GFP synthesis output. The graph shows the max rate of synthesis for each of the chassis; for in vivo this is the steady state reached after about 30 minutes and for in vitro it is the rate between 60 and 90 minutes which is the maximum rate before the energy limitations of the system cause the rate to drop. The blue line on corresponds to the range of AHL and the response of the in vitro chassis. The key difference between the chassis is the rate of GFP synthesis which is lower in the in vitro chassis e.g. for 1000nM of AHL the rate of GFP synthesis in vivo is ~450 GFP molecules per sec per cell, in vitro has an equivalent value of 220 GFP molecules per second. The shape of the transfer function is very similar for both chassis, both begin to saturate at around 1000nM of AHL and the threshold of sensitivity is around 1nM AHL. It is very surprising that a construct works so similar in different chassis, showing the affect of the chassis is minimal to the constructs behavior. |