Imperial/Cell by Date/Design

From 2007.igem.org

Cell by Date : Design

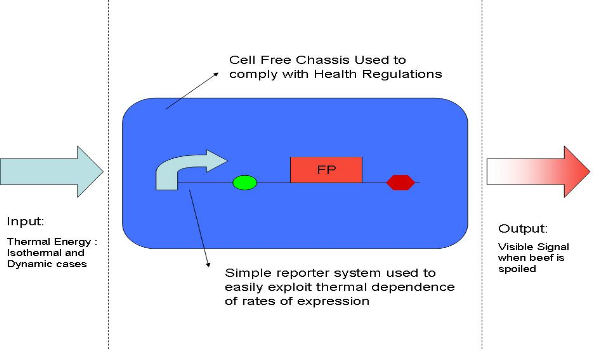

Design Overview

| Property | Value | Design Solution | System Level |

| Health Regulations | System Must not be living replicating bacteria | Use a Cell Free System e.g. Promega's S30 Cell Extract | Chassis |

| Lifespan | System must have a shelf life of 7 days | Protease Inhibitor of Cell Extract Should ensure degradation of Visual Reporter is Minimal Proper Packaging should ensure that evaporation of Cell Free system is so low that system can surive for 7 days | Chassis |

| Inputs | Isothermal Conditions between 0 & 40 °C | Exploit Thermal Dependance of rates of expression | Construct |

| Dynamic conditions eg. steps & ramps | " | Construct | |

| Outputs | System should give a visual signal when beef is off | Couple constituitive promoter to a Fluoresent Protein eg. RFP | Construct |

| Activation Energy | System Needs to have an activation Energy 30 +/- kJ mol-1 | To be Determined - this is hard to design for | Construct |

| Response Time | System needs to have a response time under 1 hour | To be Determined - this is hard to design for |

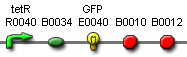

DNA Constructs

| Construct Design | Availability |

| This part can be found as BBa_I13522 in the registry. |

| This part can be found as BBa_E7104 in the Registry, albeit a different RBS and terminator. May require modifications. |

In previous iGEM projects, Temperature as an input has been explored through cold shock and heat shock promoters. These promoters essentially only operatre for a limited range of temperatures.

In making a Time Temperature Integrator we would like a promoter that works over a wide range of temperatures, increasing its rate of protein synthesis as temperature increases. We can realise this behaviour by using a simple constituitive promoter and exploiting the thermal dependance of its rate of synthesis, this type of behaviour has been characterised by Ryals as far back as 1982. (REFERENCE)

In terms of Activation Energy and Response Time we have been unable to find these in literature and to it is hard to make a design that will achieve these targets. However through the course of our experimentation we will determine these properties and hopefullly their values will suit our interests.

Chassis Selection

|

We have chosen to use the commerciall available S30 E. coli cell extract made by Promega. After having looking into a variety of different cell-free chassis, we feel that this chassis best suits our needs. In particular this chassis allows us to meet our base requirement of complying with the Health and Safety regulations of the field we are working in, we don't want a live system near our burger meat as potential leak of our system could mean that our system actually spoils the burger meat !! |

| Commercial S30 E. coli Cell Extract in bulk solution + packaging to last 7 days |

In addition to complying with health regulations the S30 cell extract is commercially available meaning that it has been shown to work. This is very important for us as it allows our focus to be on tuning the chassis to suit our needs rather than making the chassis work in the first place. |